Energy-efficient pellet factory in Tanagura: production and fuel at the same time.

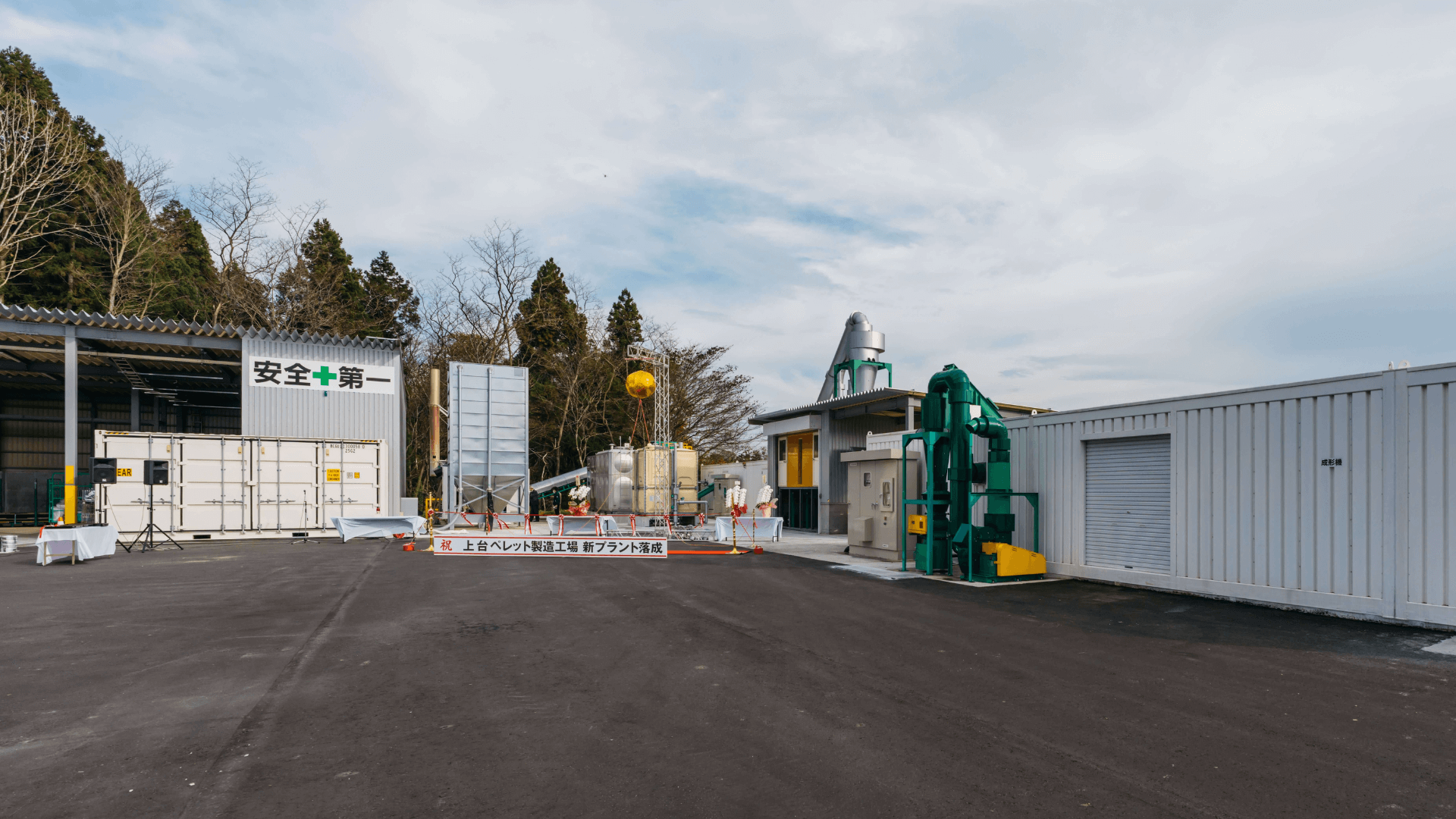

A cogeneration plant was installed at a seed pellet factory in Tanagura, Fukushima Prefecture, to reduce CO₂ emissions and the cost of pellet production.

Goal of the factory:

Reduce cost and carbon footprint for pellet fuel.

Solution:

The “WE-50P” pellet biomass cogeneration plant was installed.

Services and benefits

- The heat is used for drying sawdust.

- The use of built-in tanks for pellet production has minimized the construction time.

- Local, sustainable energy production for the mill’s own needs.

Facts Seed Pellet Factory Tanagura

Running pellet-biomass power plant

Power generation

WE-50P: 50kWel for the seed factory’s own needs

Heat generation

supplies 120 kWth

Special advantages

Electricity and heat from the CHP are used as energy sources for pellet production.