WegscheidEntrenco

Bioenergy Solutions engineered in Germany

Regenerative energy supply with biomass cogeneration plants.

We develop turnkey systems that provide a sustainable energy supply from biogenic residues for electricity, heating and cooling.

We turn innovative trends into sustainable, economical solutions.

Our biomass cogeneration units (CHP) use solid, renewable fuels such as wood chips, wood pellets and briquettes (pellets).

This saves you energy costs, makes you independent of fossil fuels and

make an important contribution to climate protection by using renewable raw materials — around the clock.

By using other biogenic residues, we are already developing our technology beyond pure wood power generation.

OUR TURNKEY BIOMASS CHP PLANTS

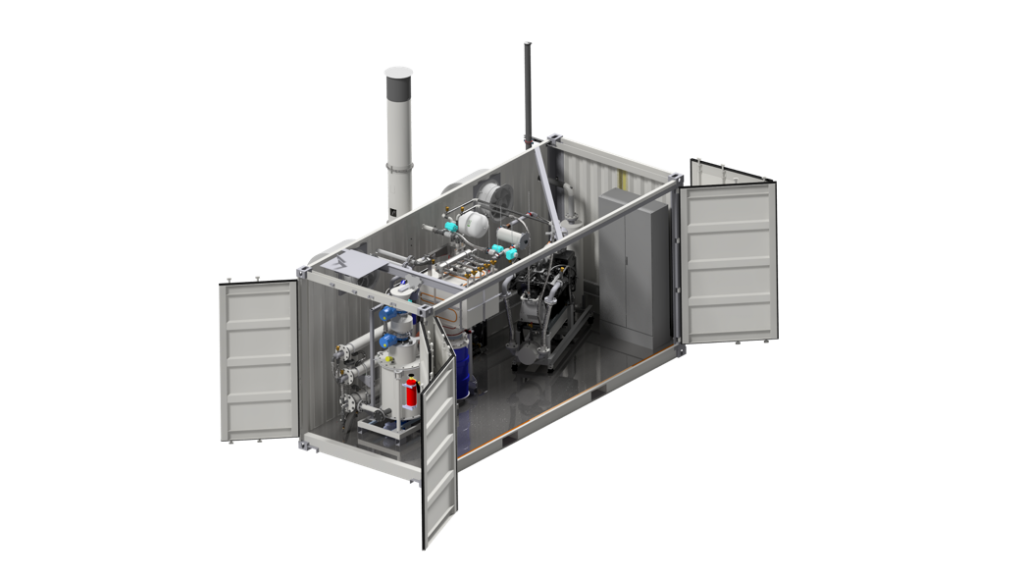

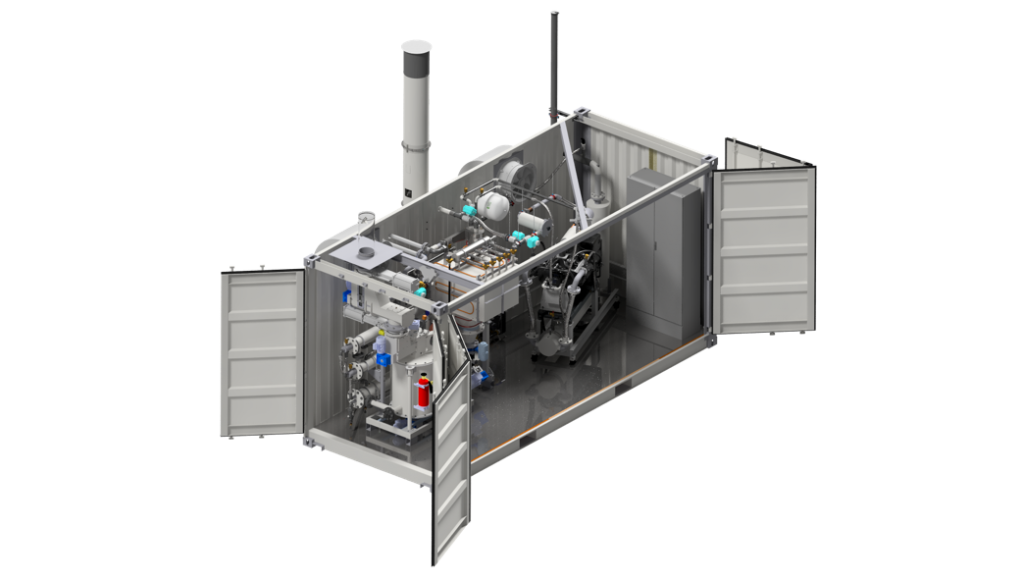

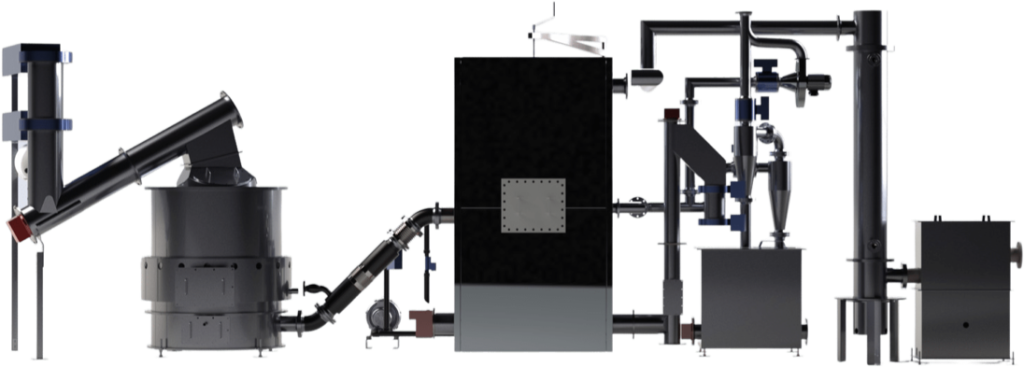

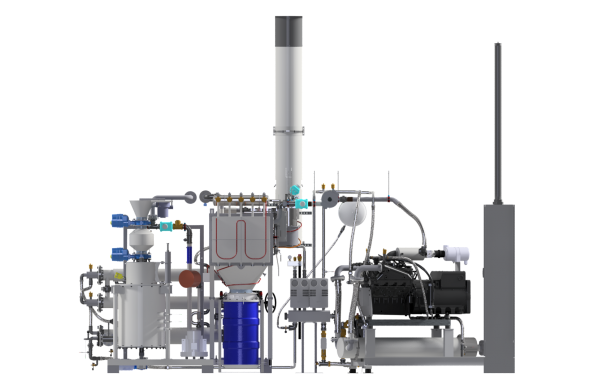

Our product range consists of three module types: 50 kWel for wood pellets (WE-50P) and for wood chips (WE-50C) as well as 135 kWel for wood chips and briquettes (WE-135C; thermal output always approximately twice as high as the electrical output). All systems produce wood gas, which is used in a CHP unit to generate electricity and heat.

We thus cover the most common requirements in many of our customers' applications.

Turnkey complete plants from 50 kWel to 2 MWel are configured according to customer requirements on the basis of our standard modules. These complete plants usually also include the complete peripheral technology, such as delivery, drying, screening and the complete conveyor technology.

50 kW Pellets (WE-50P)

Fuel: wood pellets.

Rated power: 50 kW electric and 120 kW thermal.

Particularly suitable for hotels, farms, food industry and public facilities with local and district heating.

50 kW Wood Chips (WE-50C)

Fuel: wood chips.

Rated power: 50 kW electric and 120 kW thermal.

Particularly suitable for wood processing industries, such as sawmills, furniture manufacturers and numerous other industries with access to already dried wood chips.

Peripheral equipment for drying can be supplied if required.

135 kW Wood Chips, Briquettes (WE-135C)

Fuel: wood chips

Rated power: 135 kW electric and 266 kW thermal.

Particularly suitable for forestry operations and wood processing, hotels (also with spa), breweries, dairies, market gardens, as well as for heating networks. In addition to wood chips, this plant can also be operated with wood briquettes (pressed pellets from wood residues).

The reasons why a biomass CHP system is the right solution for your company

The output of our biomass CHP units is optimally tailored to the requirements of a wide range of company sizes and sectors. Thanks to the simultaneous production of electricity and heat, the combined heat and power plant can both cover the company’s own requirements and be used to feed into the public electricity and/or heat grid. There is the possibility of fixed feed-in tariffs or direct sales with interesting market opportunities.

Independence from fossil fuels

By using biomass, a company can operate independently of fossil fuels. In this way, you simultaneously reduce risks to your energy supply and increase sustainability.

Lower energy costs

By switching to biomass CHP units, you can avoid the rising cost of fossil energy. With our biomass CHP units, you can save up to 30 percent on energy costs.

Contribution to climate protection

By using wood as biomass, the raw material cycle is CO₂-neutral. In addition, we use residual and waste wood. Due to the high efficiency of up to 85 percent, our CHP units have a lower fuel requirement.

Who is a biomass CHP system suitable for?

A biomass CHP system with wood-fired power supply is particularly worthwhile for companies that require large amounts of thermal energy on a constant basis for their operations – even in summer. Our CHP units generate electricity that can be used for the company’s own needs or supplied to the public grid. At the same time, the CHP units produce heat, e.g. for drying materials, for heating purposes or for the production of cooling.

Our equipment is suitable for the following companies and industries, including:

- Hotels, spas and wellness resorts

- Agricultural enterprises

- Food industry

- Shopping centers

- Wood processing industry, such as sawmills, carpentries, furniture manufacturers

- Public facilities, such as schools, hospitals or cultural institutions

- Residential complexes with high electricity and heat consumption

- Properties with high electricity and heat consumption

WegscheidEntrenco is ISO 9001 certified!

We are proud to announce that our company has received ISO 9001 certification from TÜV Süd. This certification confirms our commitment to the highest quality standards and efficient management processes.

Thanks to this certification, our customers can be assured that we are continuously working to improve our products and services.

Your trust, our motivation: now ISO 9001-certified.

Our trade fair presence in 2024 !

We are excited to announce that WegscheidEntrenco will be present at several important trade fairs this year.

- Green Power Fair in Poznan: 23.04 to 25.04.24

- International Wood Fair in Klagenfurt: 28.08 to 31.08.2024

- Energy decentral trade fair in Hanover: 12. to 15.11.24

Our team looks forward to welcoming you to our stands and assisting you with your questions. Be part of these exciting events and experience the future of sustainable energy together with us!

Dynamic start to the business year for WegscheidEntrenco GmbH

WegscheidEntrenco GmbH, a merger of Bioenergie Wegscheid GmbH and Entrenco GmbH since January 1, 2023, reports a successful start to its first business year with an increase in incoming orders of over 50% compared to the previous year. The company offers economically attractive and sustainable energy solutions and has already installed more than 130 plants worldwide.

For more information, please see our press release.

Contract signed with SymEnergy

BioEnergie Wegscheid (BEW) and SymEnergy signed a contract on April 7, 2023, for the purchase of a wood gasification combined heat and power (CHP) plant and associated peripheral equipment. It covers the construction of the turnkey biomass power plant Ikuno-Ginzan, which is planned near the city of Asago, Hyogo Prefecture/Japan.

For more information, please see our press release.