Peripheral Products

Optimally coordinated overall solutions including the complete peripheral equipment for fuel preparation

Chipping and Storage

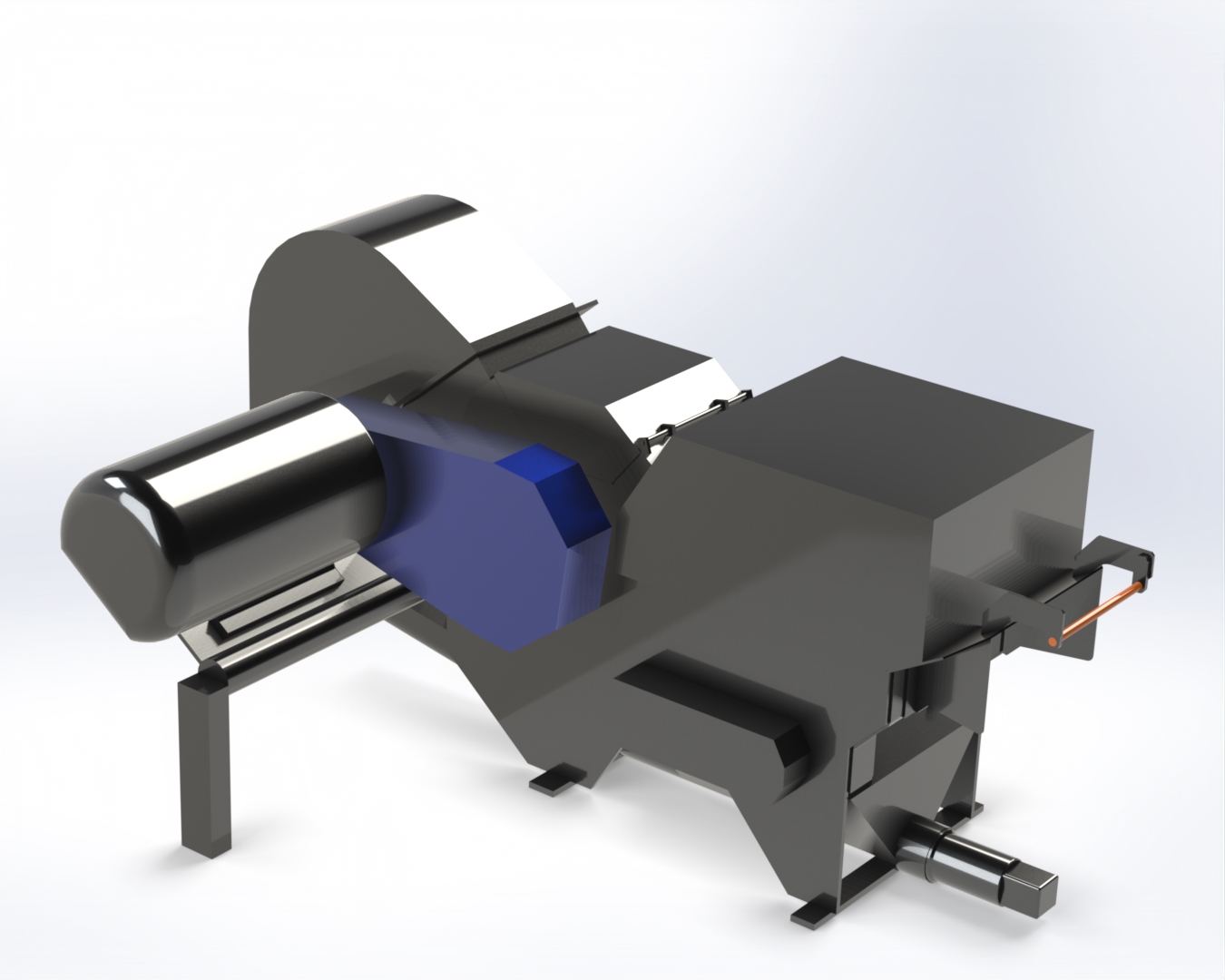

Chipper

- Produces high quality wood chips that meet all specifications

- Ideal for chipping all types of wood

- Universally applicable, even in existing plants

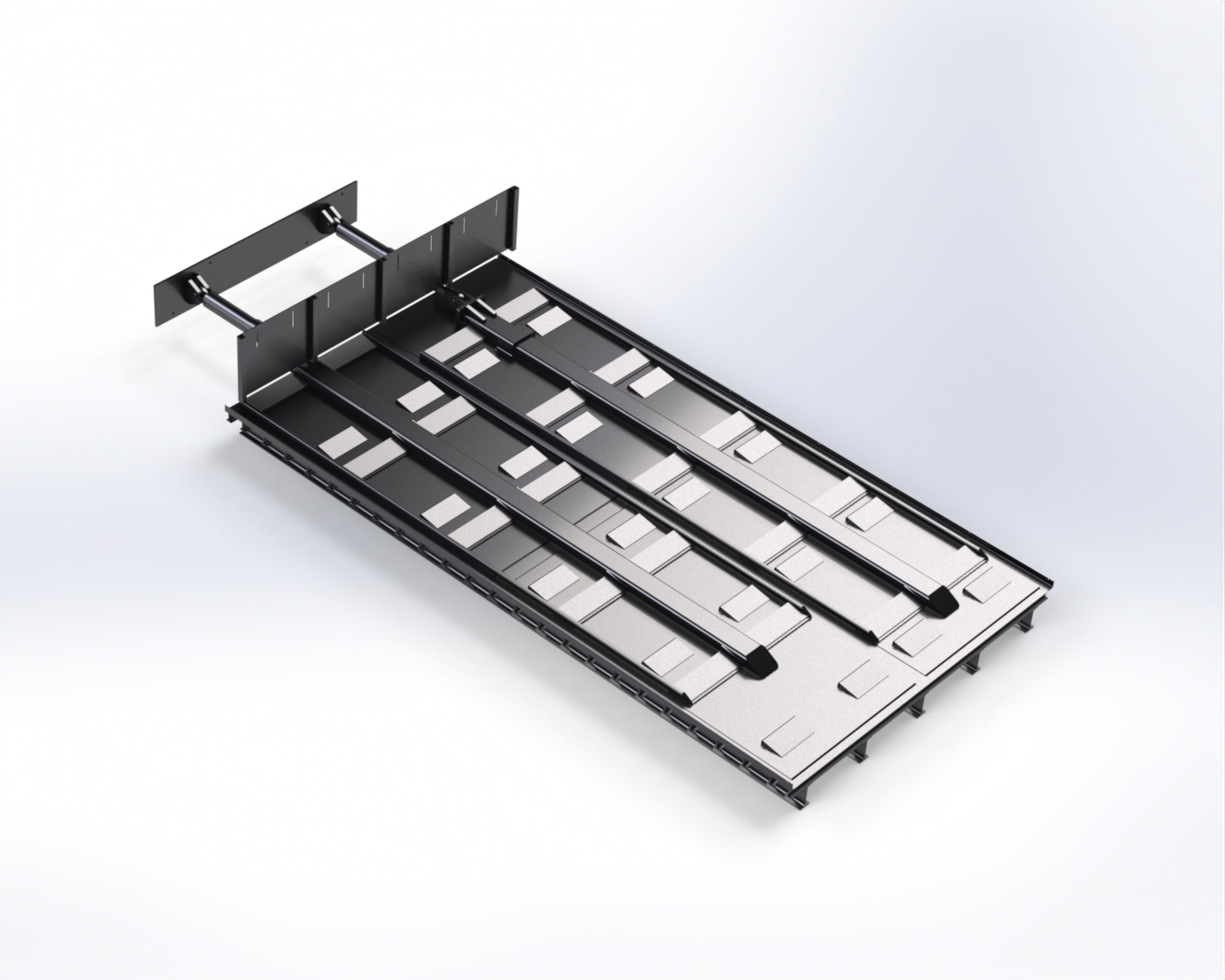

Accessible push floor / drying floor

- Storage with automatic discharge

- Available with or without ventilation

Drying of Wood Chips

Three types of dryers are available depending on the drying requirements, layout and available transport means.

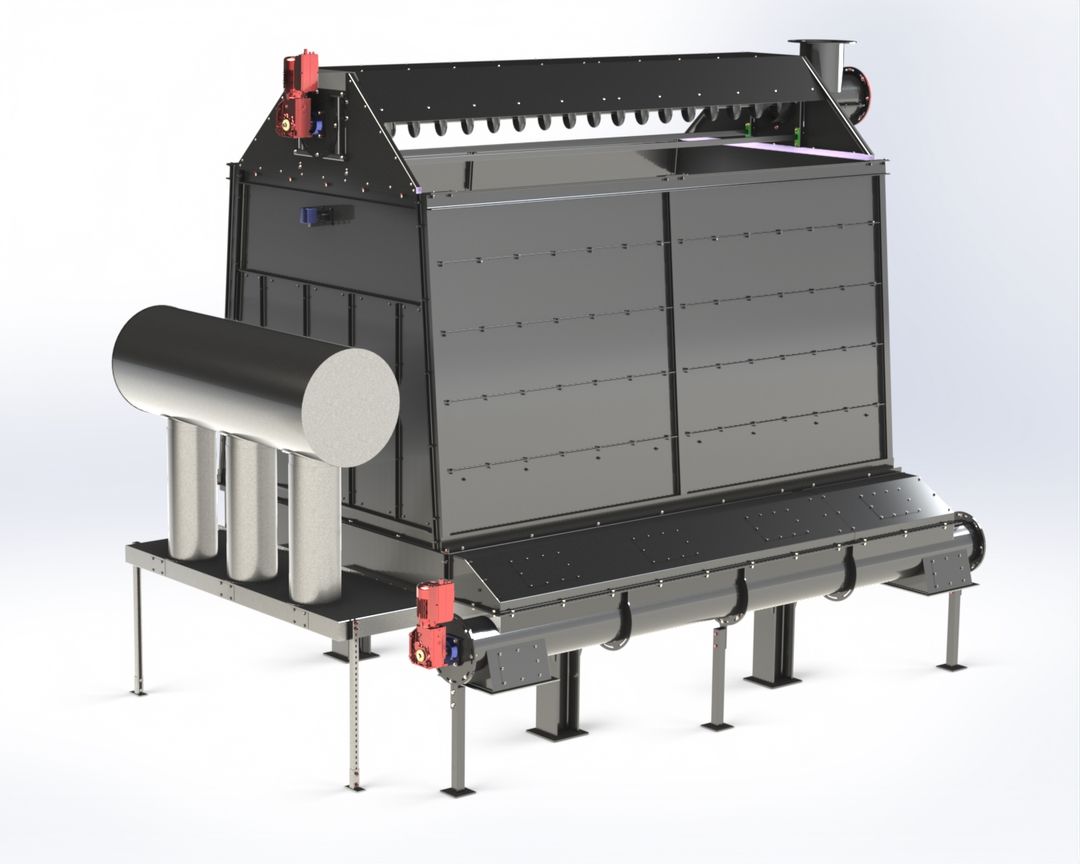

Segment dryer

- 1-2-3-4 segments

- 10-40 m3 capacity

- Side lift

- Dust removal

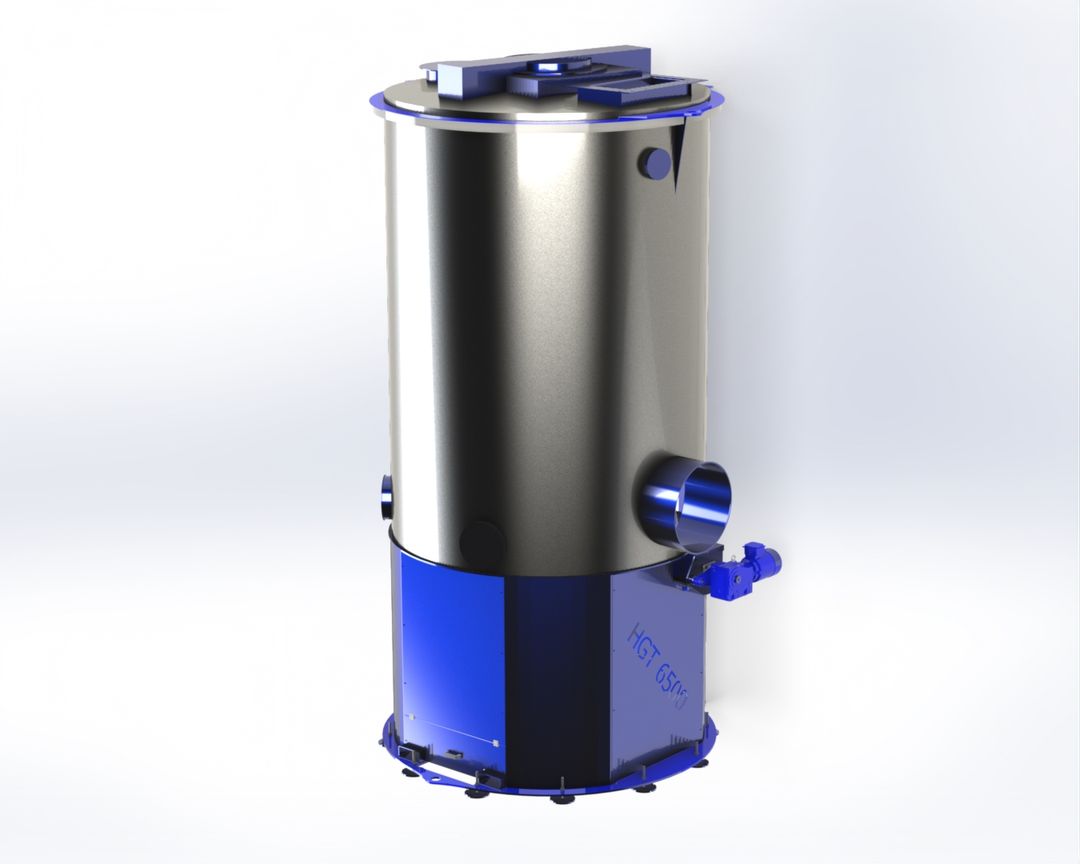

Silo dryer

- Dries continuously and uniformly to any moisture content

- Drying hopper with special airflow and three-zone drying system for optimum ventilation

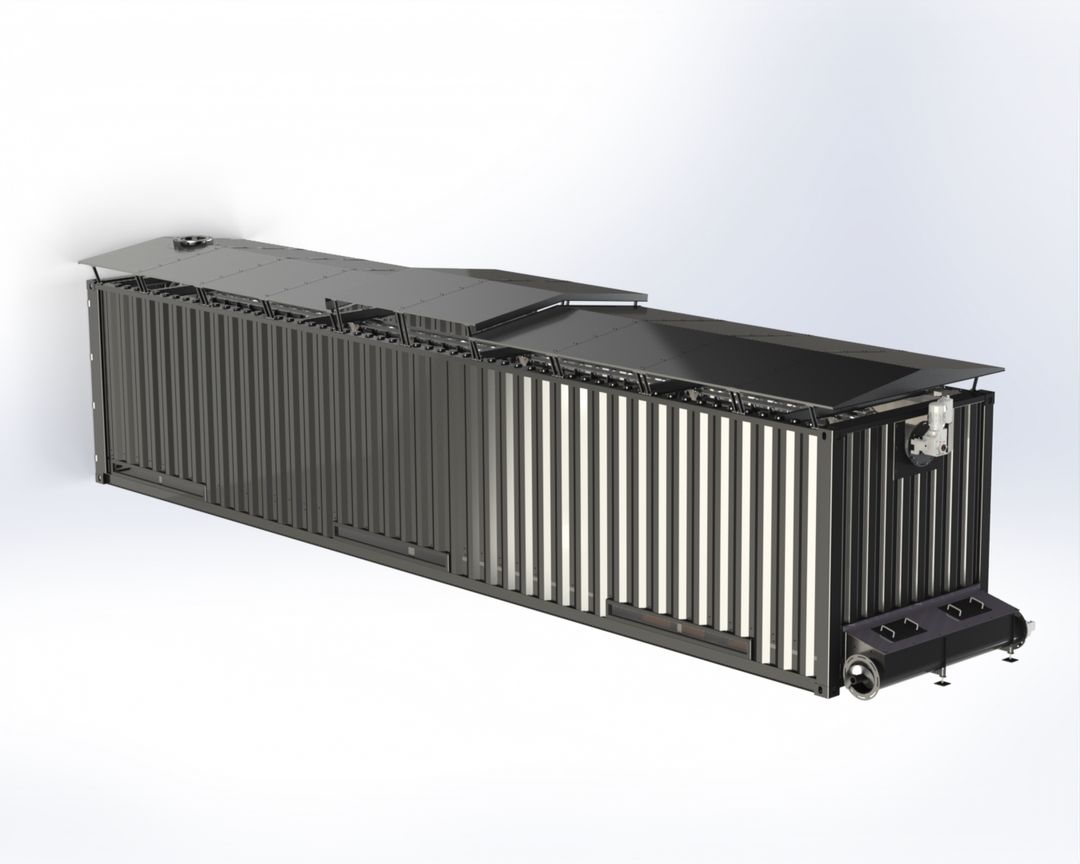

Drying container

- Flexible design: installation of a sliding floor in the container possible

- Diffusion-open fabric tarpaulin for covering

- Saves the construction of drying boxes

Screening, Storage and Wood Chip Logistics

The screening, storage and conveying of the wood chips can be customized with a system made of our own products.

Screening plant

Our screening technology filters out fine particles that could interfere with the conveyor or even reduce the efficiency of the gasification process.

We offer two design variants that are suitable for all projects and can be modified according to customer requirements.

- For screening out fine particles

- 2 construction variants without and with coarse particle discharge

- Sieve inserts according to customer requirements

Storage container

Our storage container is used to buffer wood chips before they enter the gasification process.

The storage container is equipped in such a way that it can be connected to our conveyor system via a screw discharge.

The container has a capacity of 20-40 m3.

- For buffering the wood chips before the gasifier

- Net 20 m3 capacity

- Screw discharge

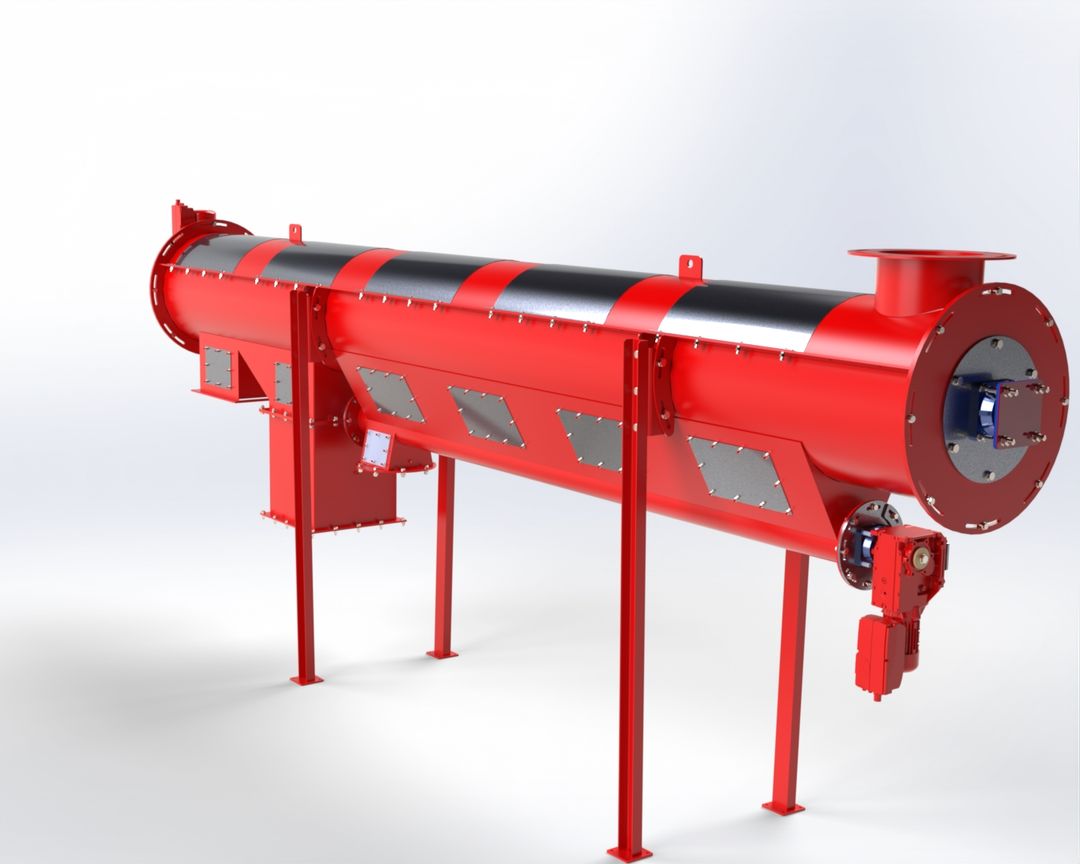

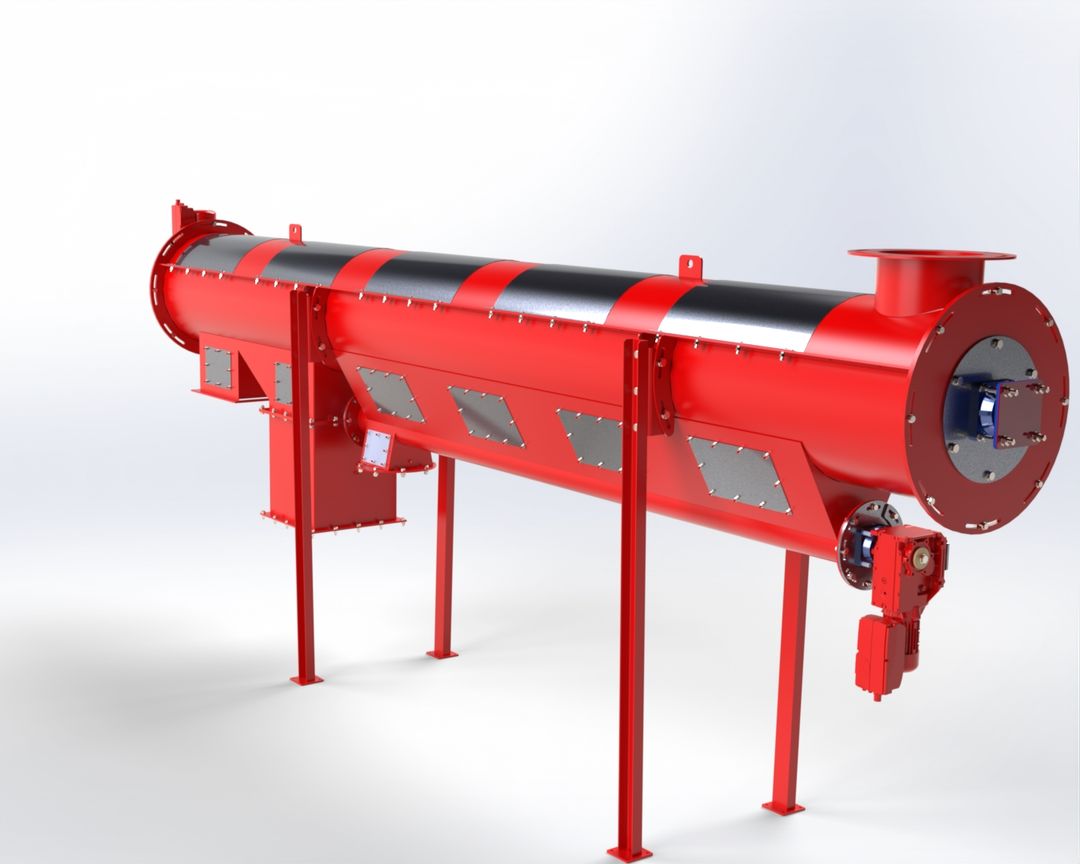

Conveyor technology

The conveyor is used to connect all system components and can be used and customized for all project sizes and requirements.

Our shaftless spirals are available in a variety of styles and sizes to make any project successful.

- For connecting all system components

- With shaftless spirals in various designs and sizes