Technology

WegscheidEntrenco uses the proven principle of combined heat and power (CHP), which produces electricity and heat simultaneously at high efficiency. Our patented technology achieves high efficiency through uniform, finely controlled gasification and harmonious coordination of the entire process chain. By using wood as biomass, the raw material cycle is CO₂-neutral.

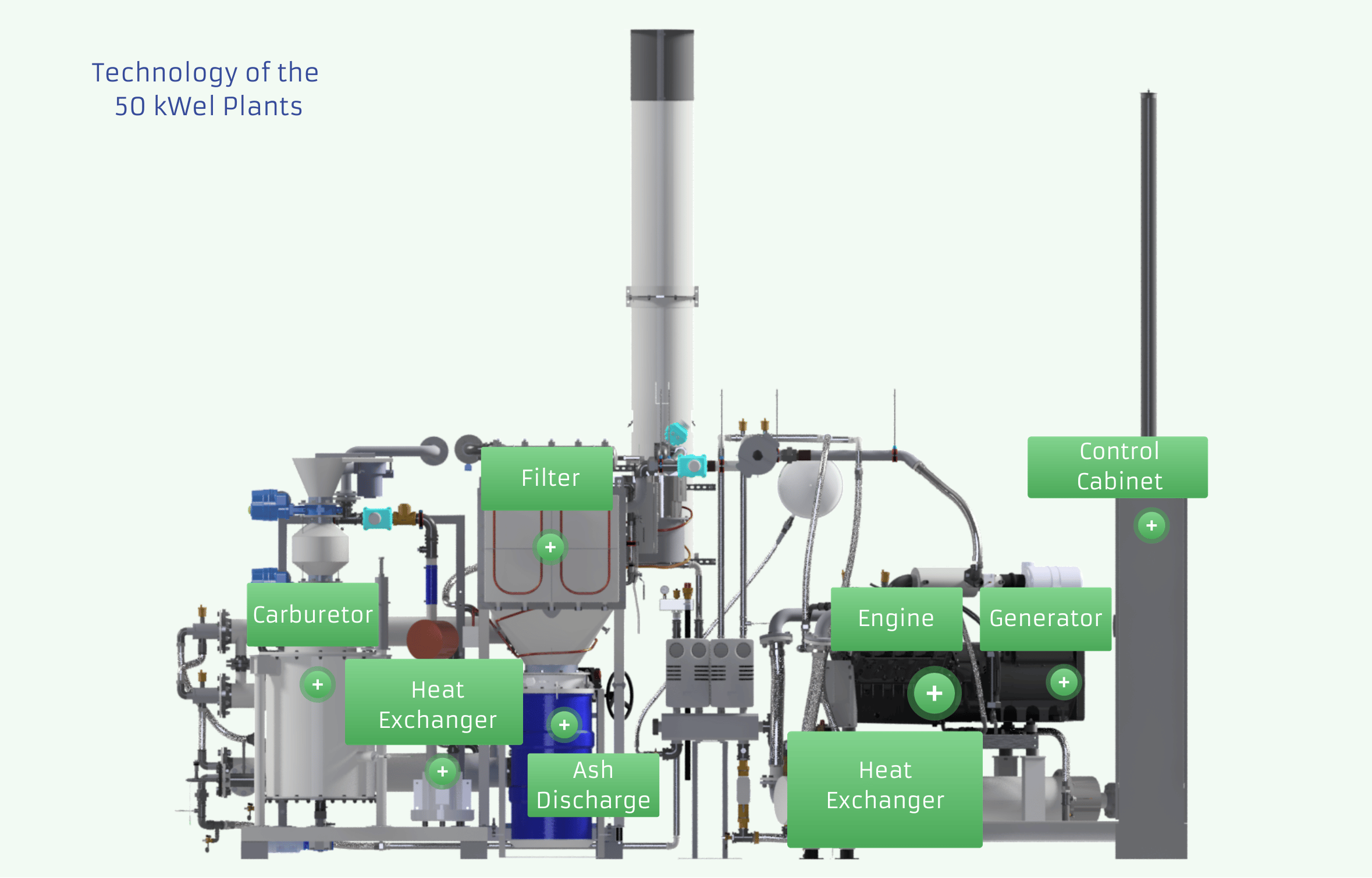

Technology of the 50 kWel plants

Carburetor

Wood gas generation

Heat Exchanger

Wood gas cooling

Filter

Wood gas is freed from ash

Ash discharge

Ash is discharged from the system

Engine

Wood gas is burned in the engine

Generator

Power generation

Heat Exchanger

Heat recovery from exhaust gas

Control Cabinet

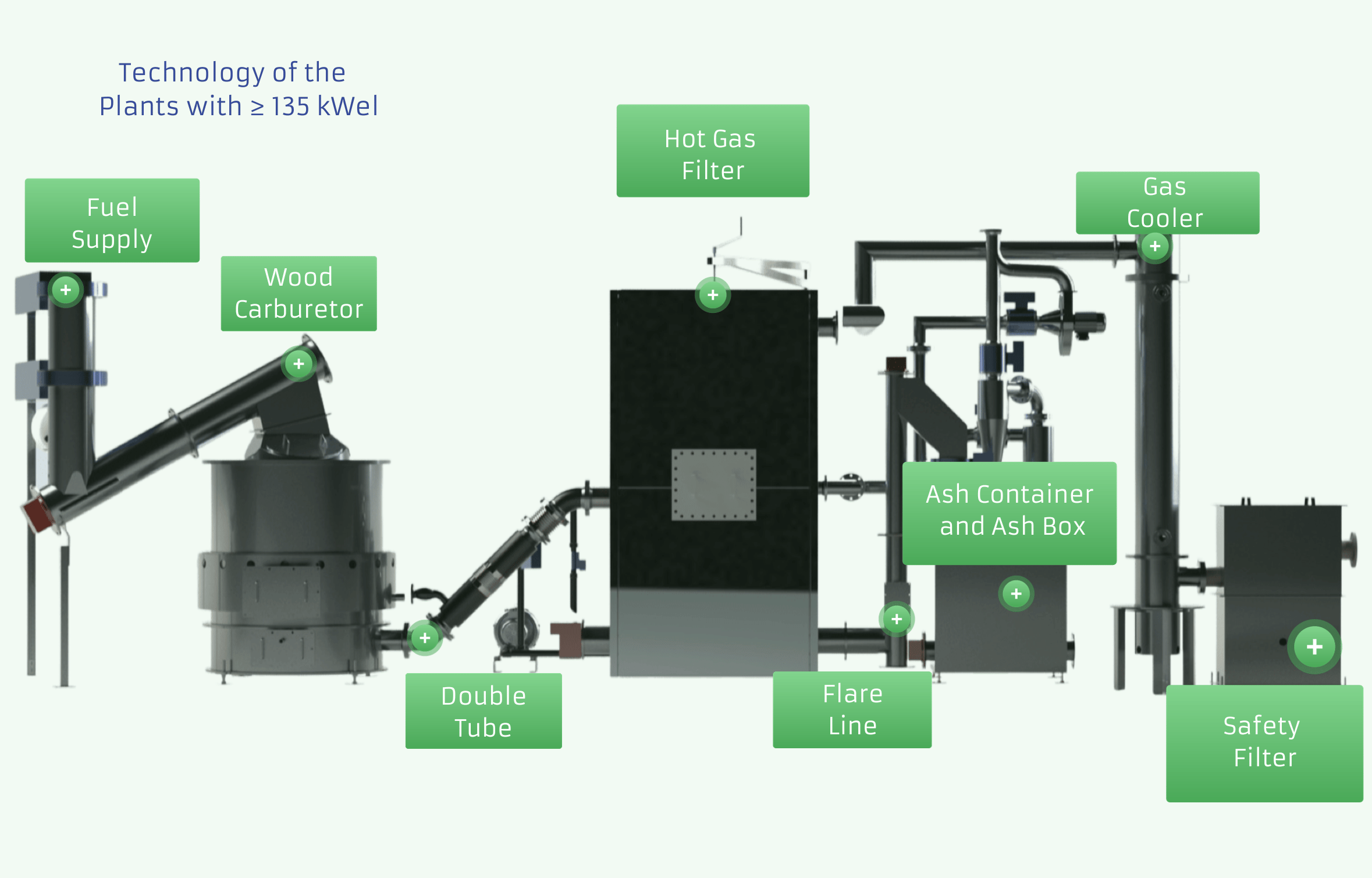

Technology of the Plants with ≥ 135 kWel

Fuel Supply

The wood chips are fed into our system via a screw conveyor.

3-part wood carburetor

Our carburetor has tested technology, which guarantees stable operation, low maintenance and long service life.

Double tube

The syngas from the gasification process is fed to our hot gas filter.

Hot gas filter

The patented design uses metallic filter cartridges with a long service life. Thanks to the high degree of separation, clean wood gas is supplied to the engine.

Ash container and ash box

Due to the efficient gasification process, only little ash is produced and the ash is free of toxic substances. No additional costs for waste disposal.

Flare line

Automatic safety feature and is used to compensate the gas flow of the plant.

Gas cooler

Hot gas must be cooled before it enters the engine. Since it is connected to the water circuit, this is the first source of heat.

Safety filter

The safety filter is unique in the industry. Other remaining microparticles are filtered out of the gas.

High reliability and economic efficiency

The engine, generator and other key components are carefully selected series products from renowned manufacturers and thus guarantee high reliability and economy. Finally, by developing and manufacturing our products in Germany, we fulfill the expectations associated with ''Egineered in Germany''.

ENGINEERED IN GERMANY

In over 15 years we have developed our products and components to perfection. Developed and tested in-house, we guarantee the longevity of our components. Other key components such as the engine and generator are carefully selected and customized series products from renowned manufacturers. Finally, we fulfill the Made in Germany claim by developing and manufacturing our products in Germany.